Here they are in their glory! I will post the documentation as soon as it gets a once over from a fresh set of eyes. This is my entry for this weekend's raw wool challenge. I spun the wool quite awhile ago, and just did the dying (my latest experiments with madder which I posted about recently).

I like that the hat and mittens are more functional and less fashionable, things an ordinary working person might have had. Or a kid out for a romp in the snow. In this case, an over-sized kid, but certainly not the little lordling I'm usually trying to dress. The mittens are ambidextrous too, which just goes to show that Elizabeth Zimmerman's suggestion to knit mittens in sets of 3's might have been around for a good long while. We have this one because a kid dropped it in a field after all.

Now I should just have time to get to activities night tonight and get myself packed up for the weekend in the morning without a huge rush! Or at least not any more than the usual amount of rush. Thankfully the doctors appointment that was scheduled for tomorrow late in the afternoon got moved to yesterday, so I am free to leave whenever I am ready and will be able to beat some of the traffic. As long as I get there in time to set the tent up in daylight I will be doing ok.

Thursday, May 26, 2011

Wednesday, May 25, 2011

Knitting frustration

A quick post to say that my project for this weekend's event (hah, nothing like the last minute you say?) is, in typical form, not going well. The mitten portion is done and looks wonderful, the hat is giving me grief. I was going to do a flat cap and got halfway done with the crown (those buggers take For.Ev.Er. to knit BTW) when I realized I wasn't going to have enough yarn to finish no matter what I did. Gah. So, I frogged the whole thing yesterday and started on a Monmouth cap. Still a hat, still a different gauge than the patterns out there so it's not a too-easy knitting part of the project, and I should be able to get it done pretty fast and not run out of yarn this time.

It's also still boring as hell to knit, like most period European knit (except the Sion bags), and means I have to start over on my hat portion of the documentation. Sigh. I can do this, right? It's not a huge A&S event, I don't need a 20 page opus or anything and there's the spinning and dying and wool processing part to talk about and that none of that has changed. Just the knitting.

Did I mention it was boring to knit? Just round after round of boring old stockinette. Sure, there's some vaguely interesting construction with the brim but I've done that sort of thing before so it's rather lost it's glamor and besides which, that's hardly enough to make a vast expanse of stockinette interesting. It would probably be soothing and mindless if I didn't have to worry about writing up the documentation as well.

It's also still boring as hell to knit, like most period European knit (except the Sion bags), and means I have to start over on my hat portion of the documentation. Sigh. I can do this, right? It's not a huge A&S event, I don't need a 20 page opus or anything and there's the spinning and dying and wool processing part to talk about and that none of that has changed. Just the knitting.

Did I mention it was boring to knit? Just round after round of boring old stockinette. Sure, there's some vaguely interesting construction with the brim but I've done that sort of thing before so it's rather lost it's glamor and besides which, that's hardly enough to make a vast expanse of stockinette interesting. It would probably be soothing and mindless if I didn't have to worry about writing up the documentation as well.

Tuesday, May 24, 2011

Finished ave beads

Somehow or another I've got the hang of this lampworking thing well enough to finish the ave beads for my paternoster project! I ended up being able to produce enough 7-9mm beads for a Seraphic rosary, or Franciscan Crown, which has seven decades (72 beads in all once you add the bit at the end). Yay!

I'm super excited about this for a couple of reasons. First of all, it's a really interesting form of paternoster and one of the few that can be documented to a specific time period. Franciscan historians date it to 1422 (see http://www.shrinesf.org/rosary.htm), when a young friar had a vision of the Virgin. Second, the focus is on the joys of the Mary rather than the more common (at least today) sorrows or wounds that you tend to see in "special" forms of the devotion (though if you do the standard 15 mysteries only 5 of those are sorrowful). I'm all about some extra joy right now, so I find this particular form of the prayer really appealing. Lastly, I really like St. Francis. My grandmother, who was a huge force in my early life had a particular affinity for St. Francis and when I visited Assisi in high school I found the experience particularly moving. I wasn't even Catholic yet, but I found it to be one of the most peaceful and prayerful places I've ever visited. The brothers that we met there were some of the kindest, warmest people I have had the honor to met.

When I set out to make the beads for a paternoster I was really hoping I would be able to do a Franciscan Crown, but I wasn't sure if the actual glass working was going to go well. I took the time to practice, and didn't try to do anything more ambitious that 72 simple beads that are more or less the same size (which is, I hope, ambition enough for my eventual judges), but so far it's looking really good. Here you can see everything laid out, waiting for the gauds. I found that if I sorted the decades into similar sizes you notice the variations in size much less.

The plan is to find some nice 12mm (or so) silver beads for the gauds, and order a cross or some other medal from The Rosary Workshop. Hearts were quite popular and they have a couple of suitable sacred hearts that should be about the right size. I'd like to avoid a tassel, though if I don't find a cross or something else that goes well with whatever gauds I end up with that's what I'll use. I had planned to tablet weave the cord for the beads, as something similar is shown in one of the MOL books, but the hole in the beads is a little too small so I'll thread them on a heavy linen cord.

I'm super excited about this for a couple of reasons. First of all, it's a really interesting form of paternoster and one of the few that can be documented to a specific time period. Franciscan historians date it to 1422 (see http://www.shrinesf.org/rosary.htm), when a young friar had a vision of the Virgin. Second, the focus is on the joys of the Mary rather than the more common (at least today) sorrows or wounds that you tend to see in "special" forms of the devotion (though if you do the standard 15 mysteries only 5 of those are sorrowful). I'm all about some extra joy right now, so I find this particular form of the prayer really appealing. Lastly, I really like St. Francis. My grandmother, who was a huge force in my early life had a particular affinity for St. Francis and when I visited Assisi in high school I found the experience particularly moving. I wasn't even Catholic yet, but I found it to be one of the most peaceful and prayerful places I've ever visited. The brothers that we met there were some of the kindest, warmest people I have had the honor to met.

When I set out to make the beads for a paternoster I was really hoping I would be able to do a Franciscan Crown, but I wasn't sure if the actual glass working was going to go well. I took the time to practice, and didn't try to do anything more ambitious that 72 simple beads that are more or less the same size (which is, I hope, ambition enough for my eventual judges), but so far it's looking really good. Here you can see everything laid out, waiting for the gauds. I found that if I sorted the decades into similar sizes you notice the variations in size much less.

The plan is to find some nice 12mm (or so) silver beads for the gauds, and order a cross or some other medal from The Rosary Workshop. Hearts were quite popular and they have a couple of suitable sacred hearts that should be about the right size. I'd like to avoid a tassel, though if I don't find a cross or something else that goes well with whatever gauds I end up with that's what I'll use. I had planned to tablet weave the cord for the beads, as something similar is shown in one of the MOL books, but the hole in the beads is a little too small so I'll thread them on a heavy linen cord.

Thursday, May 19, 2011

More fun with fire

The lampworking thing is sort of addictive! I've been practicing, with an aim towards producing uniform, round beads so that I can eventually make a paternoster. I think I'm ready to start working with the actual glass I want to use, it seems that each color rod behaves a little differently, which makes sense since different metals and minerals are used to make the colors and each one melts and burns at a different temperature. They also seem to wind onto the mandrels a little differently. If I was good at this, I would be working all the glass at the coolest possible temperatures but I've got to figure out what that is for the glass I want to work as I am not good at this yet.

Anyway, the result of my practice is, as you see, a lovely Viking-ish bead swag! With some dangley bits of things that went terribly wrong but I could not bear to throw away.

And some close ups:

The stacked beads in the center are the first beads my husband and I made (he made the silvery blue one and I made the red one). I'm pretty pleased with the clear one with red spots and the amber one with a black stripe, my first attempts at embellishing. The whole thing has been a learning process but it's fun and oddly relaxing.

Anyway, the result of my practice is, as you see, a lovely Viking-ish bead swag! With some dangley bits of things that went terribly wrong but I could not bear to throw away.

And some close ups:

Wednesday, May 18, 2011

Flemmish kercheif/coif/head thingie

I'm posty-mcposty-pants today. Oh well.

While waiting for my yarn to dye, I decided to make a Flemmish style kerchief or cap to go with my as-yet-unsewn kirtle. The general idea of the head covering comes from several pictures, but they pretty much all look like this one from from the Hours of Charles of Angouleme:

The Medieval Tailors Assistant has a pattern for such a cap which is tailed. Sort of a coif with long flaps, rather like lappets, cut on the bias, which one wraps round the head and ties. See http://www.gelfling.dds.nl/tailed%20cap.html for the one remaining website (and some broken links to sites with construction details, le sigh) about this method of making this head covering. This makes no sense to me as it's highly wasteful of fabric, and for nothing more than a do-rag. Besides which, it sort of looks like you can accomplish the same thing with a rectangular cut veil.

So, I found http://www.heatherspages.net/flemish-kerchief.html which shows an alternate way of arranging a Flemish style kerchief and http://lynnehurstinvites.com/edyth/notes/veil.html which gave me another set of instructions and some dimensions for the thing. I set to cutting and hemming (oh how I hates the hemming) and then pinning and flipping and low and behold it worked! Here you see the results:

I played around with how I arranged the kerchief a bit and discovered that if I fold back the brim, twist the ends and bring them up to the top of my head, it ends up looking just like the picture! As seen here:

I think I need to make the whole thing just a little wider for this to work perfectly, maybe only an inch or so on either side of the brim, but it looks right and makes a lot more sense to me than the tailed cap approach. Plus, you can wear this in several ways, which seems more economical and practical.

While waiting for my yarn to dye, I decided to make a Flemmish style kerchief or cap to go with my as-yet-unsewn kirtle. The general idea of the head covering comes from several pictures, but they pretty much all look like this one from from the Hours of Charles of Angouleme:

The Medieval Tailors Assistant has a pattern for such a cap which is tailed. Sort of a coif with long flaps, rather like lappets, cut on the bias, which one wraps round the head and ties. See http://www.gelfling.dds.nl/tailed%20cap.html for the one remaining website (and some broken links to sites with construction details, le sigh) about this method of making this head covering. This makes no sense to me as it's highly wasteful of fabric, and for nothing more than a do-rag. Besides which, it sort of looks like you can accomplish the same thing with a rectangular cut veil.

So, I found http://www.heatherspages.net/flemish-kerchief.html which shows an alternate way of arranging a Flemish style kerchief and http://lynnehurstinvites.com/edyth/notes/veil.html which gave me another set of instructions and some dimensions for the thing. I set to cutting and hemming (oh how I hates the hemming) and then pinning and flipping and low and behold it worked! Here you see the results:

I played around with how I arranged the kerchief a bit and discovered that if I fold back the brim, twist the ends and bring them up to the top of my head, it ends up looking just like the picture! As seen here:

Madder dying results, and fun with fire

Here are the results of my latest attempts to dye with madder:

The small skein in between the silk and the wool is from the original, pickle-tainted attempt, to show the differance in color. It's actually pretty close to how the skeins came out of the dye pot, so I'm thinking the pickle jar ended up not making that big a difference in the end. I did end up using an iron modifier on the wool, just briefly, as they skeins came out pretty bright and orangy-red to begin with. The color is a sort of terracotta/rust red now, which is pretty but still not quite what I was going for. I will be able to wear it as a flat cap though, with a buffer of linen cap, which is the main thing.

So, I am no closer to understanding how to get a true red from madder. It may be that with alum, you just don't get a true red, more of an orange based red. Maybe I need to change my mordant? Possibly it's the water from my tap and I need to check the Ph and/or mineral content there? Or maybe I'm doing something wrong? I kept the temperatures low, and according to my book if it had got too high the color would have gone dull, which it certainly did not, so I'm pretty sure that wasn't my problem. Maybe madder just gives you an orange based red and I need to accept that?

The yarn ended up fulling a bit in the dye pot as well, which is rather to be expected but a major pain to deal with. Since there are bit of madder root floating around in there too, they got all stuck to the yarn and it's been no fun trying to wind the stuff into balls. Maybe less stirring next time? Though if I stir less, I'm not sure I would get such an even color on the yarn.

I was quite surprised by the color I ended up with on the silk - it's a really pretty champagne/orange, which I like but was not at all what I was expecting to get (the silk did not go in the iron modifier). The silk will probably get used for some tablet woven garters, which will look lovely in that color. I'm guessing to get red, or even just brighter color on silk, you need to either use a different mordant or leave it in the dye longer. Or possibly use a different dye altogether.

And as a total random aside, here are my first six attempts are making lampwork beads. The seventh bead got stuck on the mandrel and had to be smashed with a hammer. The process is quite exciting, what with the large flame and all, if a little scary. Hopefully I will get the hang of the technique well enough to make enough beads for my paternoster project. These will probably end up on a Viking bead swag (or garland as I prefer to call them):

The small skein in between the silk and the wool is from the original, pickle-tainted attempt, to show the differance in color. It's actually pretty close to how the skeins came out of the dye pot, so I'm thinking the pickle jar ended up not making that big a difference in the end. I did end up using an iron modifier on the wool, just briefly, as they skeins came out pretty bright and orangy-red to begin with. The color is a sort of terracotta/rust red now, which is pretty but still not quite what I was going for. I will be able to wear it as a flat cap though, with a buffer of linen cap, which is the main thing.

So, I am no closer to understanding how to get a true red from madder. It may be that with alum, you just don't get a true red, more of an orange based red. Maybe I need to change my mordant? Possibly it's the water from my tap and I need to check the Ph and/or mineral content there? Or maybe I'm doing something wrong? I kept the temperatures low, and according to my book if it had got too high the color would have gone dull, which it certainly did not, so I'm pretty sure that wasn't my problem. Maybe madder just gives you an orange based red and I need to accept that?

The yarn ended up fulling a bit in the dye pot as well, which is rather to be expected but a major pain to deal with. Since there are bit of madder root floating around in there too, they got all stuck to the yarn and it's been no fun trying to wind the stuff into balls. Maybe less stirring next time? Though if I stir less, I'm not sure I would get such an even color on the yarn.

I was quite surprised by the color I ended up with on the silk - it's a really pretty champagne/orange, which I like but was not at all what I was expecting to get (the silk did not go in the iron modifier). The silk will probably get used for some tablet woven garters, which will look lovely in that color. I'm guessing to get red, or even just brighter color on silk, you need to either use a different mordant or leave it in the dye longer. Or possibly use a different dye altogether.

And as a total random aside, here are my first six attempts are making lampwork beads. The seventh bead got stuck on the mandrel and had to be smashed with a hammer. The process is quite exciting, what with the large flame and all, if a little scary. Hopefully I will get the hang of the technique well enough to make enough beads for my paternoster project. These will probably end up on a Viking bead swag (or garland as I prefer to call them):

Monday, May 16, 2011

More Madder

My madder vat is on the stove! Yay! After a few of hours of slow simmering, it looks like I'm getting a decent red this time, rather than the orangey color I got the first time I tried dying with madder (the result of soaking my root in a plastic jar which had previously been home to pickles). The silk I threw in for good measure is orange though. Sort of a brownish orange, heading towards salmon, but still orange. I'm not really sad about this, I suspect the silk would take the color differently but I'm surprised. It guess that explains the difference in some of the period dye recipes for silk (duh), many of them add other dyestuffs to get a good red, or don't use madder at all.

I've got the let this first round got for awhile longer yet before I know how good a red I've got on my wool. Depending on the orange tones, I may try a little bit of an iron modifier on the wool. It's destined to be a flat cap and the trim band on a pair of mittens, both of which I hope to be able to wear. Since I will have at least a linen cap on between the flat cap and my face, I can stand a little orange in the red, but the super orange I ended up with last time is really not flattering at all. According to my dye book, I should get a nice tone with the iron and lose most of the orange. We shall see.

I have 12 ounces of oatmeal colored handspun CVM to toss into the exhaust bath once this first round is done. The current plan is to try that with the mordant-and-dye-in-one-go method and see how that works. And use the iron for sure on that, just for fun. I have no particular plans for that fiber, it's been sitting around in my pile of spun wool waiting for something so I figured it might get used if I dyed it.

I've got the let this first round got for awhile longer yet before I know how good a red I've got on my wool. Depending on the orange tones, I may try a little bit of an iron modifier on the wool. It's destined to be a flat cap and the trim band on a pair of mittens, both of which I hope to be able to wear. Since I will have at least a linen cap on between the flat cap and my face, I can stand a little orange in the red, but the super orange I ended up with last time is really not flattering at all. According to my dye book, I should get a nice tone with the iron and lose most of the orange. We shall see.

I have 12 ounces of oatmeal colored handspun CVM to toss into the exhaust bath once this first round is done. The current plan is to try that with the mordant-and-dye-in-one-go method and see how that works. And use the iron for sure on that, just for fun. I have no particular plans for that fiber, it's been sitting around in my pile of spun wool waiting for something so I figured it might get used if I dyed it.

Saturday, May 14, 2011

Hose, attempt one

Here's my fist attempt at hose, using my fabulous new leg to drape and fit (sort of) the pattern. I used the 16th century pattern from Textiles and Clothing (the MOL book) as that particular set of hose had no seams under the foot. I have, as a result of a car accident almost 2 years ago, developed some less than fun problems with my feet and having seams running under the arch of my foot seems like it might be a bad plan. Probably less so with wool hose, but as I want to make linen hose for now (I live in Virginia, it gets humid and I die) seams under my arch are right out.

Anyway, here are the results. I'm not 100% happy with the fit of the foot but overall they came out pretty well. Certainly they are wearable and fit as well the ready-made pair I bought at 12th Night.

Overall I'm pretty happy with these as a first attempt. Having never made cloth hose before, it went pretty well and I'm pleased with when I ended up with. They aren't perfect but I learned a lot and feel a lot more confident going into the next pair.

Anyway, here are the results. I'm not 100% happy with the fit of the foot but overall they came out pretty well. Certainly they are wearable and fit as well the ready-made pair I bought at 12th Night.

I made one mistake/change in drafting the pattern that I need to go back and correct before I cut out the next pair (which will be yellow!) - I cut the sole and side gussets in one piece and cut the whole bottom of the foot on the bias. There is another pair of extant hose where the foot is constructed in this way, but the pair from London has the gussets and sole cut separately and on the straight grain. I think this will work better on my foot. Also, the heel seam needs to extend UNDER my heel a bit, which I did not do to avoid a seem under my foot, but I think the hose will sit better on the leg if the seam goes all the way around the curve of the heel the way the original hose to. I also want to tighten up the fit around the lower leg and ankle just a bit.

I'm also wondering if they made these footed - i.e. for right and left feet, or if they were ambidextrous. The way the seams were sewn on the original would allow you to wear it either side out, so I suppose you could fit it more closely and effectively have a left and right foot. I didn't want (and still don't) to have footed socks, as that's just one more thing to think about before my coffee, but does argue in favor of hand sewing and careful finishing. I think if I snug the whole thing up I will eliminate most of the bagging thats resulting from making the foot right/left neutral but this is something I'm really curious about now.

Overall I'm pretty happy with these as a first attempt. Having never made cloth hose before, it went pretty well and I'm pleased with when I ended up with. They aren't perfect but I learned a lot and feel a lot more confident going into the next pair.

Friday, May 13, 2011

Know thy strength

I got some madder root last night from my laurel to use for a A&S entry coming up at the end of the month, and since I really need to get moving on the project, I started prepping the root this morning. For those of you not familiar with the madder root dyeing process, the roots come in pretty big pieces which you have to crush up into small bits, so as to expose maximum surface area to your dye liquid, and then soak the little bits for a day or two before you can start dyeing. Chopping up the roots can be pretty tough business, you have to either grind them up in a food process or use a mortar or something similar. Some of the larger bits can be really hard to deal with.

One of the larger, tough bits broke my small food processor (it was a P.O.C. anyway, so this is not surprising). This is what happened after some vigorous smashing with my just-for-dyestuff mortar:

One of the larger, tough bits broke my small food processor (it was a P.O.C. anyway, so this is not surprising). This is what happened after some vigorous smashing with my just-for-dyestuff mortar:

Wednesday, May 11, 2011

A Third Leg

After much gnashing of teeth and rending of hair, and some discussion with various people (all whom have the audacity to be non-local and thus of no immediate help) I think I have, thanks to a suggestion from Edith over at The Compleatly Dressed Anachronist stumbled across a solution to my hose fitting problem! Meet my Duct Tape Leg Double!

This was actually quite easy to make, even on myself. I think it would be easier to do with some help, but it's totally doable on your own. For those of you wanting to make hose on your own, here's what I did:

Supplies:

Cling wrap

1 Roll duct tape

1 16oz bag stuffing (minimum)

Scissors

1. Wrapped you leg in plastic wrap. Get the good stuff, the cheep kind won't cling well and you will end up taping to your leg. Ouch! Wrap all the way up to your mid-thigh, you want the leg form to go above the knee, higher that your finished hose will go (better too high than not high enough). Secure the cling wrap with a small bit of tape.

2. Cut some strips of duct tape about 8 inches long with scissors you do not care about (the tape will gum up your scissors pretty bad so don't use your good ones)

3. Start taping at the bottom of your foot, keeping your ankle in a bent position as though standing. I found this was easiest to do if I sat down and kept my foot on the ground, checking my wrapping as I went by standing up after I placed every couple of pieces of tape. The tape should be as smooth as you can make it and snug, but don't wrap too tightly or you will cut off the circulation to your foot.

4. Keep wrapping with short bits of tape up your leg, keeping it in a standing position, until you have one layer of tape from your foot to wherever you want your form to stop (thigh high is probably good). Don't make it tight at the top or it won't be an accurate fit.

5. Build up a second layer of tape over the first, with the tape strips going in the opposite direction.

6. Cut the form off your leg CAREFULLY and remove from your foot. I cut down the inside of my leg to my foot rather than down the back, as I was doing this alone and could not reach the back of my leg and cut safely. Do whatever works, just don't cut yourself and try to keep the cutting line straight. This is the hardest part of the whole process.

7. Tape the cut line back together but only up to the top of the ankle. Stuff the foot and ankle firmly with whatever you are using to stuff. I used plastic grocery bags for the foot and poly fiber fill for the rest. Get a good firm stuff on the foot and ankle to support to the rest of the form.

8. Tape the rest of the leg and finish stuffing.

9. Cut on oval of cardboard out to fit the top opening of your leg form. Insert this to cover the stuffing, and tape it in place, covering it with tape.

10. Go back and add one more layer of tape over the whole form, paying particular attention to weak spots like the ankle and behind the knee. You can tweak the measurements a bit at this stage, building up or pulling in spots are not quite the right size.

11. Admire your work and make beautiful hose!

A couple of quick notes:

- I stuffed the foot with plastic bags, which seemed to give me a firmer pack. This is a good thing. More weight might also be good, so if you can add something to weight the foot so the whole thing stands on it's own, put that in the foot stuffing.

- If I do this again I will try that expanding foam insulation stuff they have at the hardware store

- A dowel or some other rigid support might be useful to support the ankle. Mine is a little wobbly, which is not a huge issue as I don't anticipate this thing lasting that long but if you want to use it for many pairs of hose the extra rigidity might help.

This was actually quite easy to make, even on myself. I think it would be easier to do with some help, but it's totally doable on your own. For those of you wanting to make hose on your own, here's what I did:

Supplies:

Cling wrap

1 Roll duct tape

1 16oz bag stuffing (minimum)

Scissors

1. Wrapped you leg in plastic wrap. Get the good stuff, the cheep kind won't cling well and you will end up taping to your leg. Ouch! Wrap all the way up to your mid-thigh, you want the leg form to go above the knee, higher that your finished hose will go (better too high than not high enough). Secure the cling wrap with a small bit of tape.

2. Cut some strips of duct tape about 8 inches long with scissors you do not care about (the tape will gum up your scissors pretty bad so don't use your good ones)

3. Start taping at the bottom of your foot, keeping your ankle in a bent position as though standing. I found this was easiest to do if I sat down and kept my foot on the ground, checking my wrapping as I went by standing up after I placed every couple of pieces of tape. The tape should be as smooth as you can make it and snug, but don't wrap too tightly or you will cut off the circulation to your foot.

4. Keep wrapping with short bits of tape up your leg, keeping it in a standing position, until you have one layer of tape from your foot to wherever you want your form to stop (thigh high is probably good). Don't make it tight at the top or it won't be an accurate fit.

5. Build up a second layer of tape over the first, with the tape strips going in the opposite direction.

6. Cut the form off your leg CAREFULLY and remove from your foot. I cut down the inside of my leg to my foot rather than down the back, as I was doing this alone and could not reach the back of my leg and cut safely. Do whatever works, just don't cut yourself and try to keep the cutting line straight. This is the hardest part of the whole process.

7. Tape the cut line back together but only up to the top of the ankle. Stuff the foot and ankle firmly with whatever you are using to stuff. I used plastic grocery bags for the foot and poly fiber fill for the rest. Get a good firm stuff on the foot and ankle to support to the rest of the form.

8. Tape the rest of the leg and finish stuffing.

9. Cut on oval of cardboard out to fit the top opening of your leg form. Insert this to cover the stuffing, and tape it in place, covering it with tape.

10. Go back and add one more layer of tape over the whole form, paying particular attention to weak spots like the ankle and behind the knee. You can tweak the measurements a bit at this stage, building up or pulling in spots are not quite the right size.

11. Admire your work and make beautiful hose!

A couple of quick notes:

- I stuffed the foot with plastic bags, which seemed to give me a firmer pack. This is a good thing. More weight might also be good, so if you can add something to weight the foot so the whole thing stands on it's own, put that in the foot stuffing.

- If I do this again I will try that expanding foam insulation stuff they have at the hardware store

- A dowel or some other rigid support might be useful to support the ankle. Mine is a little wobbly, which is not a huge issue as I don't anticipate this thing lasting that long but if you want to use it for many pairs of hose the extra rigidity might help.

Sunday, May 8, 2011

Another mystery

I'm getting ready for my next sewing project (other than the blasted hose, which hardly rise to the level of a project IMO, except in the whole finding-help-with-pattern aspect of the thing), which will be a kirtle. So far the plan is to do this in linen, as linen is less expensive than wool, will be comfy at Pennsic, and I have some I am willing to commit to a gown at my current size.

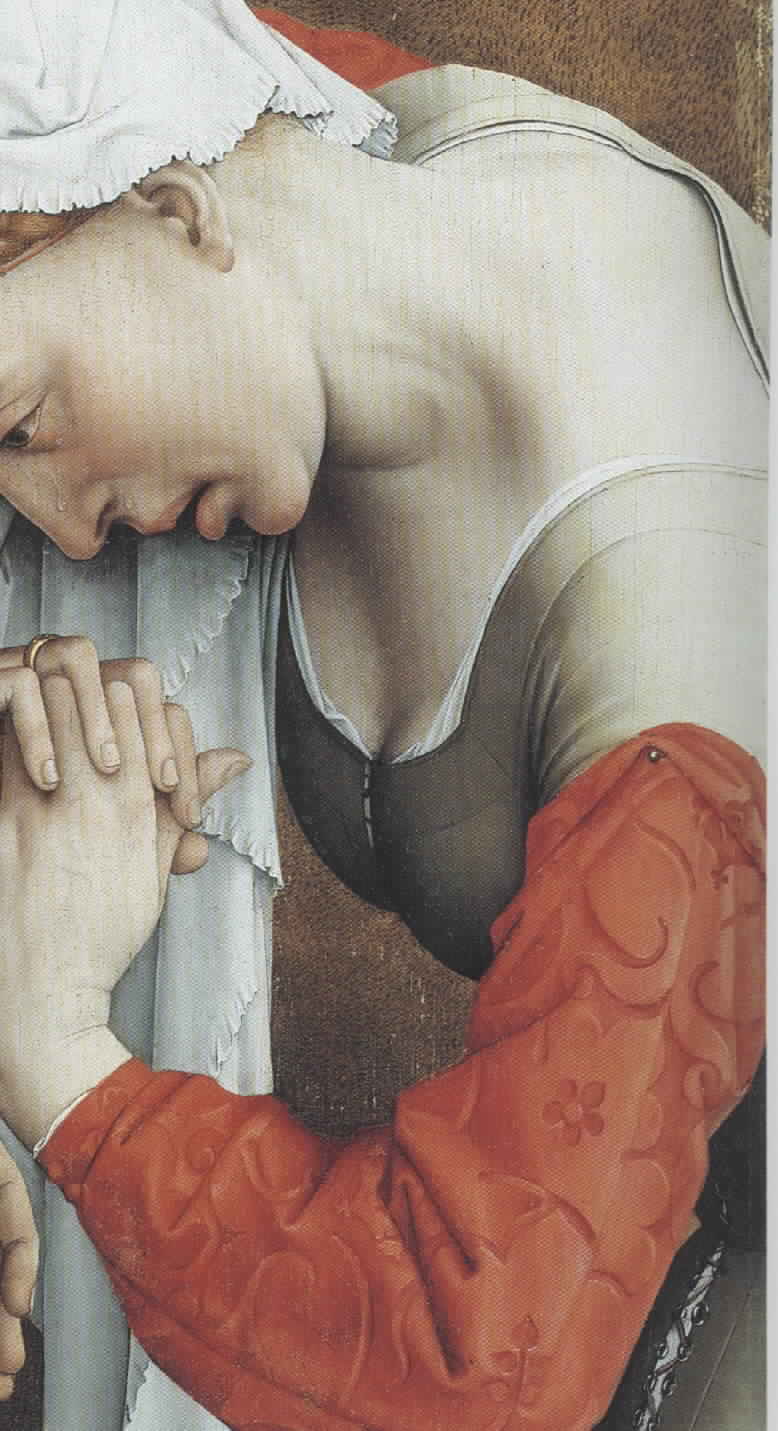

Anyway, I've pretty well decided to go with the waist-seam method of doing this, with trapezoidal skirt panels similar to those shown in the MOL book, as that will be much easier to fit on my self with minimal-to-no outside help. Which brings me to the questions. The bodice. I've been looking at paintings to get the best idea I can of where all the seam lines should be and have run across something strange (to me anyway). In nearly all of the artwork there is a facing or something around the neck that I don't tend to see included on the reproductions of these gowns. You can see it quite clearly here, in a detail from Rogier van der Weyden's Descent from the Cross:

It also looks like there is a small raglan-type seam at the arm. I can't be quite sure if it's just in the facing piece, or if that's actually actually how the sleeve is shaped. It (the raglan-looking seam I mean) would actually make sense if the facing bit was a narrow shoulder strap extending from the back, or cut separately and attached to both front and back, rather like what you see on some later period bodices. In a larger view of the picture, you can see the same angled seam front and back. One thing there clearly is NOT is a seam at the top of the shoulder. Again, this isn't the only place I've seen this sort of seaming in paintings, it seems rather more typical than exceptional, though I've found examples showing a regular shoulder seam as well. (the other thing I really like about this picture is that is appears she's using both eyelets AND lacing rings, with the transition between the two at the waist)

Here's a good back view of this sort of gown, another van der Wyden, this one a detail from "The Presentation at the Temple." Here you can see that the angled seem goes down all the way into the armscye at least:

So, what does all this mean? Is it a sort of raglan sleeve? Or just a separate strap bit? Is the seam around the neck a facing or just a line of stitching or something else? If the strap is separate, I can see where the extra bit around the neck opening would be helpful (it would be helpful regardless really). Should I try this? Or just do the easy seam-over-shoulder bodice?

Anyway, I've pretty well decided to go with the waist-seam method of doing this, with trapezoidal skirt panels similar to those shown in the MOL book, as that will be much easier to fit on my self with minimal-to-no outside help. Which brings me to the questions. The bodice. I've been looking at paintings to get the best idea I can of where all the seam lines should be and have run across something strange (to me anyway). In nearly all of the artwork there is a facing or something around the neck that I don't tend to see included on the reproductions of these gowns. You can see it quite clearly here, in a detail from Rogier van der Weyden's Descent from the Cross:

It also looks like there is a small raglan-type seam at the arm. I can't be quite sure if it's just in the facing piece, or if that's actually actually how the sleeve is shaped. It (the raglan-looking seam I mean) would actually make sense if the facing bit was a narrow shoulder strap extending from the back, or cut separately and attached to both front and back, rather like what you see on some later period bodices. In a larger view of the picture, you can see the same angled seam front and back. One thing there clearly is NOT is a seam at the top of the shoulder. Again, this isn't the only place I've seen this sort of seaming in paintings, it seems rather more typical than exceptional, though I've found examples showing a regular shoulder seam as well. (the other thing I really like about this picture is that is appears she's using both eyelets AND lacing rings, with the transition between the two at the waist)

Here's a good back view of this sort of gown, another van der Wyden, this one a detail from "The Presentation at the Temple." Here you can see that the angled seem goes down all the way into the armscye at least:

So, what does all this mean? Is it a sort of raglan sleeve? Or just a separate strap bit? Is the seam around the neck a facing or just a line of stitching or something else? If the strap is separate, I can see where the extra bit around the neck opening would be helpful (it would be helpful regardless really). Should I try this? Or just do the easy seam-over-shoulder bodice?

Thursday, May 5, 2011

Cloth hose dilema

I need to make, among other things, several pairs of cloth hose for myself. I have one pair which I purchased that fit pretty well, but the foot is not 100% accurate. I don't know if I care about this or not, the design seems pretty easy to deal with and more of the extant examples I've looked at have some really odd, fiddly things going on in the heel or ankle. I'm sure there's a reason for this, and that once I got a pattern sorted it would all make sense, but this brings me to the problem...

Patterning. Specifically, patterning something that really needs to be done while on the body. From what I've been able to find so far, to get hose to fit well, you really have to fit them carefully on the foot and leg for which they are being made. Since they will be on my leg, this is going to be tricky. Coordinating with someone who has the skills to do this for me is going to be very tricky.

So, do I give up on well-fitted hose and go with a commercial pattern,doing what I can on my own and accepting a certain amount of bagginess? Or copy the pair I have and accept a known amount of bagginess? Copying the instep piece is going to be a little tricky without taking the whole thing apart but not any worse than starting from scratch. It really would be nice to have a good pattern, I need several pairs and the pattern will serve me well for a long time once I get it sorted out.

Patterning. Specifically, patterning something that really needs to be done while on the body. From what I've been able to find so far, to get hose to fit well, you really have to fit them carefully on the foot and leg for which they are being made. Since they will be on my leg, this is going to be tricky. Coordinating with someone who has the skills to do this for me is going to be very tricky.

So, do I give up on well-fitted hose and go with a commercial pattern,doing what I can on my own and accepting a certain amount of bagginess? Or copy the pair I have and accept a known amount of bagginess? Copying the instep piece is going to be a little tricky without taking the whole thing apart but not any worse than starting from scratch. It really would be nice to have a good pattern, I need several pairs and the pattern will serve me well for a long time once I get it sorted out.

Wednesday, May 4, 2011

What's doing

I freely admit that I'm a project collector. One of the email lists I'm on has been discussing this, and it would seem I'm not alone, but I never really bothered to really think about this before. I counted last night and had no less four in-progress projects within arms reach of where I was sitting and another four or five within easy reach in the same room (not counting anything spinning related). My poor husband. Our living room has been totally taken over. Oh well. At least most of them are pretty small things.

For the things that have deadlines and aren't distractions or just hemming sorts of things (veils and bits of Roman garb), here's what I'm currently working on:

For A&S 30 Triathlon:

For the things that have deadlines and aren't distractions or just hemming sorts of things (veils and bits of Roman garb), here's what I'm currently working on:

For A&S 30 Triathlon:

- Finishing the eyelet brick stitch bag (making some good progress here actually)

- Perugia towel (research and supply collecting phase)

- Lampwork Rosary (as above, need to schedule a work-day)

- MOL mitten (can be seen here)

- Flat cap (the plan for this event, which is creeping up on a little faster than I would like, is to madder dye some wool I spun from a fleece to make the hat and the little contrast band on the mitten. Otherwise it's a supper-dull project. I'm planning on going to Maryland Sheep and Wool this weekend, so I should be able to get some madder root there, or get some from my Laurel (who I'm going with) and do the dying next week, then I can knit and be done with that)

- Weave napkin for auction/raffle fundraiser (really lacking motivation here for several silly reasons)

- Get A&S 50 documentation up to date

- Make clothes for Pennsic (mostly underwear, but I need at least one supportive gown. I need fabric for this)

- Finish knitting protective bags for feast gear

- a totally modern alpaca sweater

- Finish spinning gotland wool for weaving warp

- Finish sorting and washing Hog Island fleece

A&S 50 7: Tablet Weave Two Colored Striped Band from London Dig MOL Braid 449

The original band was woven in two colors of plied silk, pink and pale yellow (possibly originally white) and had bronze bar mounts attached to it. Twelve tablets were used, making a fairly narrow band of 8.5 millimeters. Each tablet was threaded with two colors of silk threaded in groups of three, SSSZZZSSSZZZ and turned continuously in one direction to create a striped pattern. The band shows one reversal of the turning direction, probably to un-twist the remaining warps.

The cards as threaded in two colors as shown below:

A | ||||||||||||

B | ||||||||||||

C | ||||||||||||

D | ||||||||||||

S | S | S | Z | Z | Z | S | S | S | Z | Z | Z | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

The cards turn continually forward. The original band shows one reversal of direction. When enough twist has built up in the warp to prevent smooth turning of the cards, reverse direction to untwist the warp and continue turning backwards.

I had selected this band as my first attempt at tablet weaving as it seemed like a fairly simple threading and turning pattern. For this first attempt, I used size 3 crochet cotton from DMC in two colors, a light blue and grey. Threading the warp was quite simple using the continuous warping method described by Crocket and Lewins. Actual weaving proceeded smoothly, with some allowance given for the learning process. The start of the band is a great deal looser and wider than the end, which can be attributed to my inexperience. By the finish of the band I figured out how to beat the weft down to get a smooth surface and maintain an even band width.

Overall, I am quite pleased with how this band works up and am looking forward to using the design again, perhaps for a belt or set of garters in silk, using the original pink and yellow.

Overall, I am quite pleased with how this band works up and am looking forward to using the design again, perhaps for a belt or set of garters in silk, using the original pink and yellow.

Sources:

Crowfoot, Elizabeth. Textiles and Clothing, c.1150-1450 (Medieval Finds from Excavations in London). Boydell Press, 2001.

Carolyn Priest-Dorman. Three Recipes for Fourteenth- and Fifteenth-Century Tablet Weaving. (http://www.cs.vassar.edu/~capriest/3recipes.html) Last accessed Aug. 31 2010.

Crocket, Candace. Card Weaving. Interweave Press, 1991.

Lewins, Shelagh. The Ancient Craft of Tablet Weaving: Getting Started (http://www.shelaghlewins.com/tablet_weaving/TW01/TW01.htm) Last accessed Nov. 18, 2010.

Monday, May 2, 2011

A&S 50 Six: Tablet Weave Satin Effect Band from London Dig MOL 423

The original braid was woven in fine silk and found attached to a bronze strap end which would have been used with a girdle. Braids of this type gained in popularity and were used for belts up to the early Tudor period. The satin pattern in accomplished by card idling – only some of the cards are turned with each pick. While this is quite simple to do the process is actually quite time consuming and I found it very difficult to keep track of where I was in my pattern.

The cards are all threaded with four stands of plied silk, alternating Z and S. 39 cards were used for the original band. For my initial attempt at this band, I used size 3 DMC pearle cotton in a salmon pink and black and 24 cards total as I only had 24 cards of the same size at the time. The cards were from Halcyon Yards, and measured 3 ¼ inches square. The first two and last two cards were threaded in black, and the remaining 20 cards were threaded in the salmon pink, then all the cards were arranged so they alternated Z and S, as in the threading diagram below:

| 1 | | | | | | | | | | | | | | | | | | | | | | | | |

| 2 | | | | | | | | | | | | | | | | | | | | | | | | |

| 3 | | | | | | | | | | | | | | | | | | | | | | | | |

| 4 | | | | | | | | | | | | | | | | | | | | | | | | |

| | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S | Z | S |

The cards are turned as followed:

Cards 1, 2, 23, and 24 turn forward every turn

First turn: All remaining even cards turn forward

Second turn: All odd card turn forward

I found this band problematic for a number of reasons. First, I had a great deal of difficulty keeping track of where I was in the pattern when I left my weaving (and even sometimes when I simply looked away). A more experienced weaver might have fewer problems with this. I suspect part of the issue is that it takes two turns for any sort of pattern to being to emerge, so it is more difficult to read your weaving and figure out which turn you are on.

Second, the cards were far too large for my hands, making the turning much more difficult. Smaller cards would make working with two packs easier.

Third, I could not sort out an efficient way of handling two packs of cards. Separating the packs out (one in front and one in back) seems the most efficient but I had trouble getting a clear shed, and again because the cards were large I still had trouble manipulating them. I ended up turning each card individually which was quite tedious.

Lastly, the pattern does not show at all well in cotton. I ended up weaving only a few inches of this band because of the difficult I had with the cards and weaving itself, and the poor appearance of the band in the fiber I had chosen. I plan to try again using silk now that I have smaller cards and a better idea of how to work with two packs of cards.

Sources:

Crowfoot, Elizabeth. Textiles and Clothing, c.1150-1450 (Medieval Finds from Excavations in London). Boydell Press, 2001.

Carolyn Priest-Dorman. Three Recipes for Fourteenth- and Fifteenth-Century Tablet Weaving. (http://www.cs.vassar.edu/~capriest/3recipes.html) Last accessed Aug. 31 2010.

Subscribe to:

Posts (Atom)